How will your product behave when subjected to real-world dynamic forces such as gravity and friction? More to the point, how much of your product development budget will be left by the time you find out? Creo MDO, an extension to Creo Parametric, significantly reduces the amount of physical prototyping you need to do.

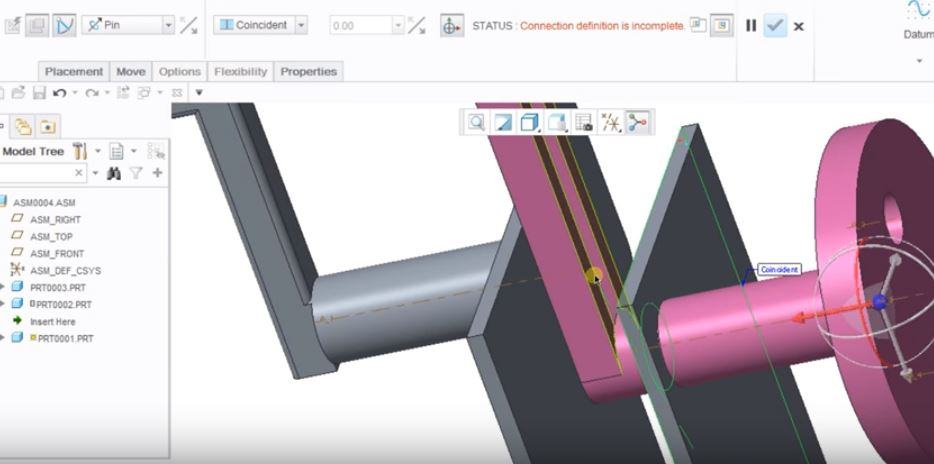

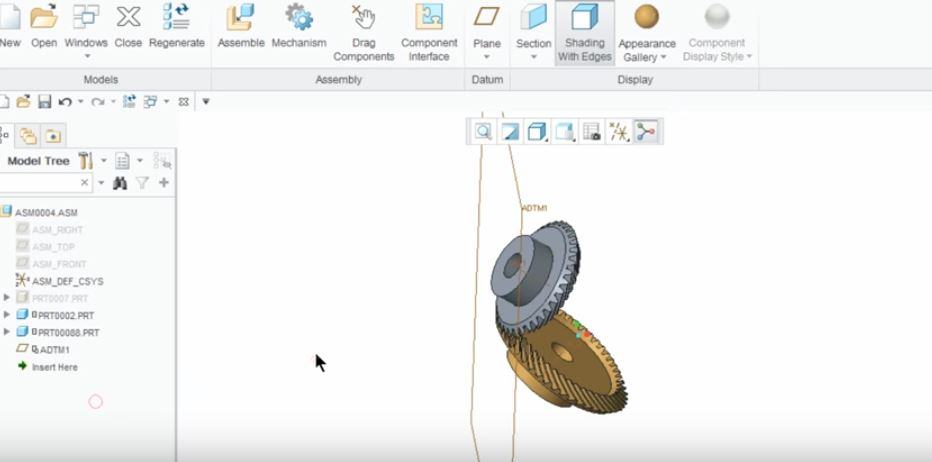

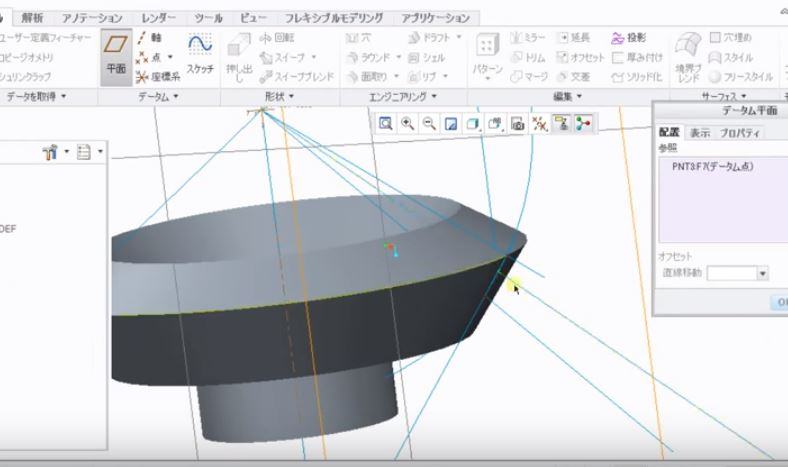

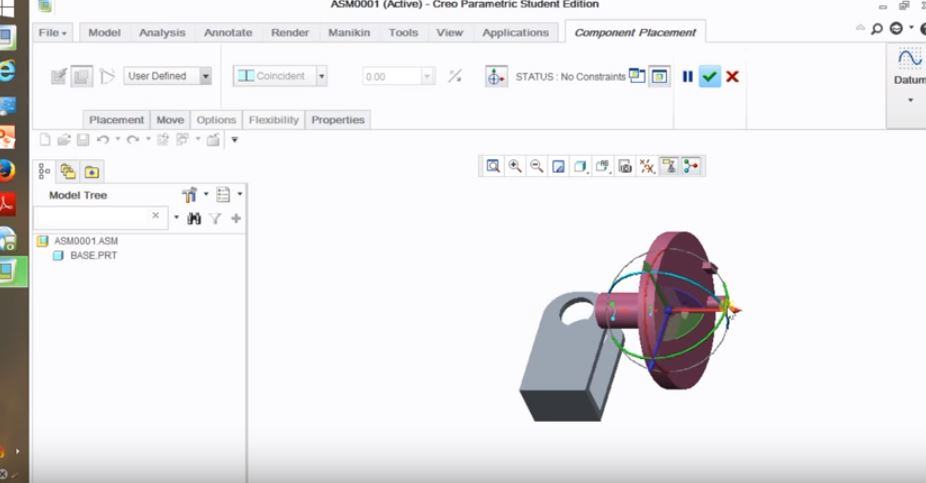

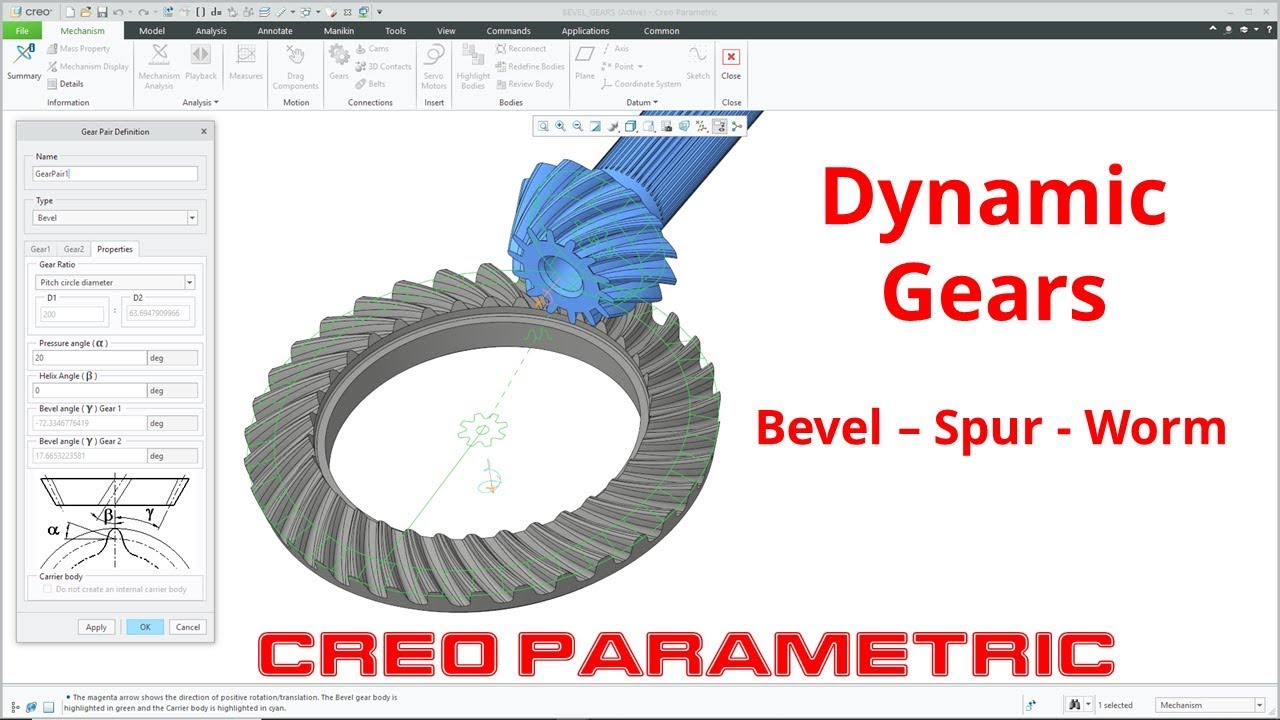

Creo MDO allows you to perform dynamic motion analysis (friction, gravity, and forces). You can also simulate springs, dampers, belts, and gears or detect problems with interference and clearance. Simply work on your design with the familiar Creo interface and then quickly evaluate it under static and dynamic forces.

Why waste time and money on physical prototypes you don’t need? With Creo MDO, you have additional time to explore the implications of your design and more money in your budget. You will also improve speed to market and have more success once you get there.

Table of Contents

Benefits of Creo Mechanism Dynamics Option

With Creo Mechanism Dynamics Option, you will:

- Reduce development costs by creating virtual prototypes for desktop testing;

- Incorporate changes into the products faster and earlier and get immediate results from desktop testing;

- Deliver higher quality products to market first by reducing development time;

- Reduce warranty costs by generating a better estimate of your product’s life;

- Eliminate costly manufacturing errors with specific, animated production instructions for assembly;

- Create more innovative products by using the time-savings gained from virtual testing to evaluate more design ideas;

- Work within an easy-to-learn, highly intuitive user interface; and

- Eliminate time, effort, and money spent on data translation and associated errors by using fully integrated design and analysis tools.

Download -creo mechanism tutorial pdf,

Loading...

Loading...